The Checkmate series achieves the much-needed step of inspecting and segregating defect free print products from all printed material for the end user – typically for Pharma, Health Care, FMCG and Mobile phone industries. This helps avoid loss of brand value and legal implications that can arise out of defective cartons. This machine can identify defects like Color Variation, Mix-up of Cartons, defects on Metpet Cartons, Braille Defects, UV & Aqueous Coating Defects, Dead Insects / Stains and Printing Defects on Mono Cartons.

Autoprint is committed to bring modern cutting-edge technology to its customers. A result of this commitment is Autoprint CHECKMATE 50 a revolution in imaging technology for defect free print products to the end customer with 100% accuracy.

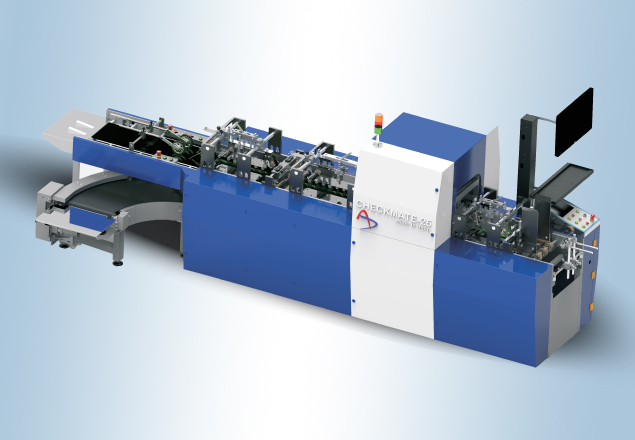

Autoprint is committed to bring modern cutting-edge technology to its customers. A result of this commitment is Autoprint CHECKMATE 25 a revolution in imaging technology for defect free print products to the end customer with 100% accuracy.

Print Inspection

Print inspection refers to the process of examining printed materials, such as books, packaging, labels, and documents, to ensure that they meet specific quality standards. The purpose of the print inspection is to detect defects, errors, or inconsistencies that may affect the readability or appearance of the printed material.

The print inspection involves various techniques and technologies, including visual inspection by human inspectors, automated inspection using specialized equipment, and computer-based analysis of digital images. The inspection process typically involves checking for issues such as color accuracy, print clarity, image registration, text alignment, and any other defects that may affect the overall quality of the printed material.Print inspection is particularly important in industries where high-quality printing is critical, such as the pharmaceutical, food and beverage, and automotive industries. It helps to ensure that products are properly labeled and that important information, such as dosage instructions or safety warnings, is clearly visible and accurate.

Vision Inspection Systems

Vision inspection systems are automated systems that use cameras and specialized software to inspect and analyze various types of products, parts, or materials to detect defects, errors, or anomalies. These systems use high-resolution cameras, lighting, and advanced algorithms to capture and process images of the products or parts in real-time, and then compare them against predetermined criteria or specifications.Vision inspection systems can be programmed to detect a wide range of defects, including scratches, cracks, chips, missing features, incorrect dimensions, and other issues that could impact product quality or safety. They can also perform tasks such as barcode reading, label verification, and package inspection.

Vision inspection systems are commonly used in manufacturing, packaging, and quality control processes, where they can improve efficiency and accuracy while reducing the need for manual inspection. They are used in various industries, including automotive, electronics, food and beverage, pharmaceutical, and many others. With their ability to provide real-time inspection and feedback, vision inspection systems

Types of Automated Inspection

In the paper printing industry, there are several types of automated inspection systems that are used for quality control and assurance purposes. Here are some of the most common types:

- Print Registration Inspection: This type of automated inspection system uses cameras and specialized software to detect and correct any misregistration of colors in a printed image, ensuring that the colors are properly aligned and registered.

- Defect Inspection: This type of inspection system uses cameras and software to detect any defects in the printed image, such as streaks, smudges, or missing ink, and removes them from the final printed product.

- Barcode Verification: This type of inspection system uses specialized software and scanners to ensure that barcodes on printed materials, such as labels or packaging, are correctly printed and scannable.

- Web Inspection: This type of inspection system uses cameras to inspect the entire web ofpaper or other materials as it passes through the printing process, detecting and identifying any defects, such as holes or tears, which may affect the final product.

- Optical Character Recognition (OCR): This type of inspection system uses optical character recognition technology to read and verify printed text on documents, labels, and packaging, ensuring accuracy and consistency.

Machine Vision andOptical Inspection Method.

Machine vision refers to the use of computer vision and imaging technology to perform automated inspection and analysis of products or materials. One method of machine vision used for inspection is optical inspection.The optical inspection involves the use of cameras, lenses, lighting, and specialized software to capture images of a product or material, and then analyze those images to detect and identify defects or irregularities. The software analyzes the images based on pre-set criteria and can detect issues such as scratches, stains, discoloration, and other imperfections.

In optical inspection, lighting plays a critical role in highlighting the areas of interest and minimizing the impact of any reflections or shadows. The camera captures the images of the product or material in multiple angles, and the software then combines these images to create a three-dimensional model that can be further analyzed.Optical inspection is used in a wide range of industries, including manufacturing, electronics, automotive, and medical devices, among others. It provides a fast, accurate, and repeatable method of inspection that can improve product quality and consistency while reducing costs associated with manual inspection.