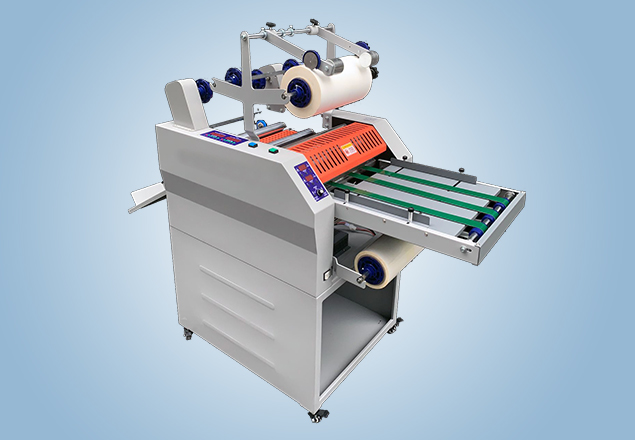

Advanced Digital Creasing & Cutting Machine for Modern Print Finishing

Precision engineered for commercial printing, packaging, and finishing workflows. MODLC 39 delivers reliable, high-speed digital creasing and cutting for superior productivity.

The Autoprint MODLC 39 is an innovative sheet-fed digital creasing and cutting solution designed to streamline pre-press and finishing operations. Built for accuracy, durability, and flexible performance, this machine enables print businesses to enhance throughput, reduce manual processes, and achieve consistent, high-quality results across a wide range of substrates.

Precision engineered for commercial printing, packaging, and finishing workflows. MODLC 39 delivers reliable, high-speed digital creasing and cutting for superior productivity.

Single Side

370 mm

13 metres/minute

Advanced control systems ensure accurate crease and cut placement every time.

Reduces setup time and manual intervention, boosting overall productivity.

Designed for continuous operation in demanding print environments.

Simplifies operation and reduces the learning curve for new users.

Digital creasing eliminates cracking and improves fold accuracy. Essential for professional print applications.

Achieve precise cut lines with minimal waste, ensuring each sheet meets exacting standards.

Accommodates a range of sheet sizes and weights, making it suitable for diverse print jobs.

Easily configure settings and monitor operations through the responsive interface.

Built with robust components to withstand heavy usage and long production cycles.

Get expert guidance and customized printing & finishing solutions tailored to your production needs.

Autoprint’s advanced printing and finishing machines are engineered to support the evolving demands of commercial printing and packaging units. Built for precision, speed, and reliability, our solutions help businesses achieve consistent output quality while optimizing productivity.

Autoprint provides comprehensive support with:

| Lamination with Auto Cut | Single Side |

| Max. Laminating Width | 370 mm |

| Unwinder Diameter | 300 mm (max), Core Dia 1 and 3 |

| Operating Speed | 13 metres/minute |

| Paper Thickness | 125-350 gsm |

| Laminating Temperature | 90-110°C (manual) |

| Heater Warm Up Time | 5 minutes |

| Total Power | 1.6 Kw |

| Temperature Control | Upper/lower (optional) |

| Upper Heating Roll | Steel |

| Lower Heating Roll | Rubber Roll |

| Control Panel | Digital LED System |

| Feeding System | Manual |

| Overlap Feeding Function | Yes |

| Bussing Function | Yes (Auto Separation) |

| Slitting Function | Yes |

| Anti-Curling Function | Yes |

| Conveyor Belt | Yes |

| Power Supply | 220V 50 Hz (Single Phase) |

| Dimensions (L x W x H) | 100 x 61 x 125 cm |

Our experts will help you choose the right machine based on your applications, volumes, and growth plans.